Post by Berdugo on Oct 16, 2006 11:37:09 GMT -5

(This is taken from pageproducer.arczip.com, I hope the author wont get mad)

This is the continuation of the Mechbox Overhaul article I

wrote a few years ago.

Introduction

Breaking in the gear set has two advatages. The first and

foremost is a noticeable reduction of whine and chatter

eminating from the gears. The second is more debateable,

when properly breaking in gears it is possible to work

(strain) harden the gears for improved strength.

When crystals yield, dislocations move through them. Most

crystals have several slip planes. Dislocations on these

intersecting planes interact, and obstruct each other, and

accumulate in the material.

The result is work-hardening: the steeply rising stress-

strain curve after yield. All metals and ceramics work-harden.

It can be a nuisance: if you want to roll thin sheet, work

-hardening quickly raises the yield strength so much that you

have to stop and anneal the metal (heat it up to remove

the accumulated dislocations) before you can go on. But it is

also useful: it is a potent strengthening method, which can

be added to the other methods to produce strong materials.*

Basic definition of work/strain hardening is: the modification

of metal structure by cold working resulting in an increase

in strength and hardness with loss of ductility.

Work hardening is similar to forging in the way that it comp-

resses the metal molecules into a very compact and hard

formation. This can only be accomplished if the metal surfaces

are lubricated and the gear temperature stays cool enough that

the molecular structure does not change. If the temperature of

the metal gets hot enough to change the molecular structure, it

will soften the surface instead of hardening it. This may seem

like a balancing act but it all happens easily & passively as

long as the oil keeps the gears cool while it is breaking in.

Procedure

Breaking in gears should be done after the gearbox parts are

finalized. If you plan on using just stock parts you can break

in the gears as is. If you plan on upgrading the bushings and

gears I would suggest doing it after you have all the parts

installed and shimmed to perfection.

Things Needed:

Vise

4.8v or 6.0v battery pack

Degree of Difficulty: Moderate, requires opening the gearbox.

Step 1: Prep

Break the gun down and get the gearbox out of the gun. Open up the

gearbox and remove the whole Cylinder Unit. This includes: tappet

plate, cylinder, cylinder head, piston, piston head, nozzle and

sping. With the Cylinder Unit out you should have only the Drive

System and Electrical Assembly left in the gearbox.

While the gearbox open you can also clean out the grease and install

a lower viscosity lube for faster break in. I use a medium weight

silicone oil.

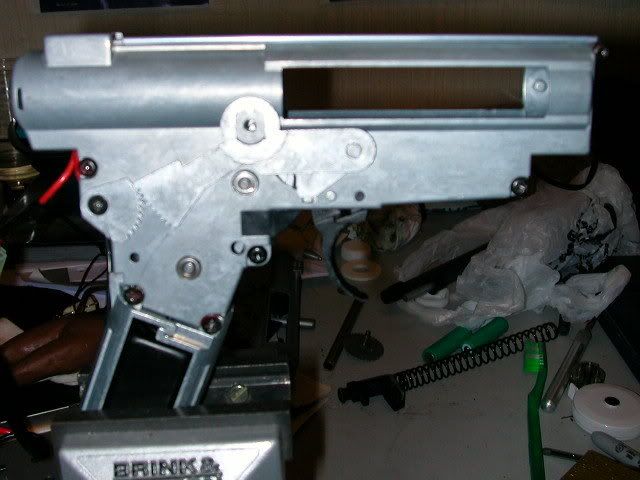

This is what the gearbox should look like after youre done

removing the Cylinder Unit.

Step 2: Break In

With the cylinder unit removed the gearbox is now ready to be broken

in. I have to note that with different guns and different gearbox

versions you may or may not be able to run the gearbox wihtout the

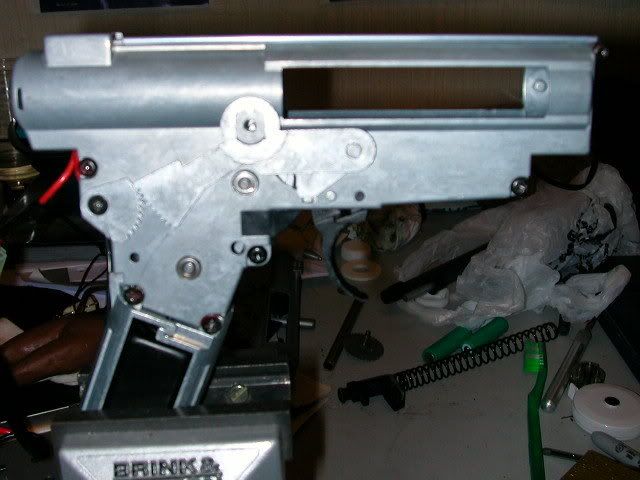

lower receiver on. The box shown in the pic above is a AK47 version

3 with contained motor. For guns like the TM m4a1 you must reinstall

the gearbox into the lower for it to be able to run.

AK47 Version 3 box being broken in.

Clamp the gun to a vise as shown and then plug the battery in. Ideally

the battery should be 1/2 or 3/4th the voltage you are planning on

running in your gun. I used a 4.8v pack for the AK47 and M4S. The vise

is not 100% needed but it makes things easier.

The actual break in process is simple. Run the gun for 1 - 1 1/2

minutes and let it cool down for 30secs to a minute. This should be

repeated till you get about 5mins of total break in time. On version

2 gearboxes without the motor bracket the motor can get very hot so

give ti some time to cool down. On version 3 boxes with the enclosed

motor bracket the bracket allows transfer of heat from the motor

through the motor bracket and into the mechbox. This makes the mech-

box kind of like a giant heat sink so motor temps on a V.3 box are

generally lower.

M4 type gearbox being broken in.

Step 3: Finishing Up

After the gear set have been broken in it is adviseable to clean them

throughly before reinstallation. If you have a motor spray cleaner I

would suggest cleaning out the motor and relubing the bushings. This

is not mandatory but something that can be done to prolong the life

of the motor. Running the Gear Set for 5 mins will also break in

the motor. This is a not as refined as breaking the motor by itself

under zero load but the results are similar.

With everything cleaned and reinstalled your gun should now have

much less gear whine. If done correctly in combination with a

good shim job and ball bearings the results will be more dramatic.

This is the continuation of the Mechbox Overhaul article I

wrote a few years ago.

Introduction

Breaking in the gear set has two advatages. The first and

foremost is a noticeable reduction of whine and chatter

eminating from the gears. The second is more debateable,

when properly breaking in gears it is possible to work

(strain) harden the gears for improved strength.

When crystals yield, dislocations move through them. Most

crystals have several slip planes. Dislocations on these

intersecting planes interact, and obstruct each other, and

accumulate in the material.

The result is work-hardening: the steeply rising stress-

strain curve after yield. All metals and ceramics work-harden.

It can be a nuisance: if you want to roll thin sheet, work

-hardening quickly raises the yield strength so much that you

have to stop and anneal the metal (heat it up to remove

the accumulated dislocations) before you can go on. But it is

also useful: it is a potent strengthening method, which can

be added to the other methods to produce strong materials.*

Basic definition of work/strain hardening is: the modification

of metal structure by cold working resulting in an increase

in strength and hardness with loss of ductility.

Work hardening is similar to forging in the way that it comp-

resses the metal molecules into a very compact and hard

formation. This can only be accomplished if the metal surfaces

are lubricated and the gear temperature stays cool enough that

the molecular structure does not change. If the temperature of

the metal gets hot enough to change the molecular structure, it

will soften the surface instead of hardening it. This may seem

like a balancing act but it all happens easily & passively as

long as the oil keeps the gears cool while it is breaking in.

Procedure

Breaking in gears should be done after the gearbox parts are

finalized. If you plan on using just stock parts you can break

in the gears as is. If you plan on upgrading the bushings and

gears I would suggest doing it after you have all the parts

installed and shimmed to perfection.

Things Needed:

Vise

4.8v or 6.0v battery pack

Degree of Difficulty: Moderate, requires opening the gearbox.

Step 1: Prep

Break the gun down and get the gearbox out of the gun. Open up the

gearbox and remove the whole Cylinder Unit. This includes: tappet

plate, cylinder, cylinder head, piston, piston head, nozzle and

sping. With the Cylinder Unit out you should have only the Drive

System and Electrical Assembly left in the gearbox.

While the gearbox open you can also clean out the grease and install

a lower viscosity lube for faster break in. I use a medium weight

silicone oil.

This is what the gearbox should look like after youre done

removing the Cylinder Unit.

Step 2: Break In

With the cylinder unit removed the gearbox is now ready to be broken

in. I have to note that with different guns and different gearbox

versions you may or may not be able to run the gearbox wihtout the

lower receiver on. The box shown in the pic above is a AK47 version

3 with contained motor. For guns like the TM m4a1 you must reinstall

the gearbox into the lower for it to be able to run.

AK47 Version 3 box being broken in.

Clamp the gun to a vise as shown and then plug the battery in. Ideally

the battery should be 1/2 or 3/4th the voltage you are planning on

running in your gun. I used a 4.8v pack for the AK47 and M4S. The vise

is not 100% needed but it makes things easier.

The actual break in process is simple. Run the gun for 1 - 1 1/2

minutes and let it cool down for 30secs to a minute. This should be

repeated till you get about 5mins of total break in time. On version

2 gearboxes without the motor bracket the motor can get very hot so

give ti some time to cool down. On version 3 boxes with the enclosed

motor bracket the bracket allows transfer of heat from the motor

through the motor bracket and into the mechbox. This makes the mech-

box kind of like a giant heat sink so motor temps on a V.3 box are

generally lower.

M4 type gearbox being broken in.

Step 3: Finishing Up

After the gear set have been broken in it is adviseable to clean them

throughly before reinstallation. If you have a motor spray cleaner I

would suggest cleaning out the motor and relubing the bushings. This

is not mandatory but something that can be done to prolong the life

of the motor. Running the Gear Set for 5 mins will also break in

the motor. This is a not as refined as breaking the motor by itself

under zero load but the results are similar.

With everything cleaned and reinstalled your gun should now have

much less gear whine. If done correctly in combination with a

good shim job and ball bearings the results will be more dramatic.