Post by Berdugo on Oct 9, 2006 5:55:25 GMT -5

(taken from airsoftretreat.com)

Challenge: How do Airsoft guns work?

Thanks to all those who participated!

Contributors to this article include:

519M4 and Pikachoad (who provided the gearbox picture as well as content)

-Jason 'Kornkob' Robinson, Retreat Challenge Editor

We play this game yet few players really understand the internal workings of an Airsoft gun. Where a paintball gun is really a superb example of a simple, hardy machine, an Airsoft gun is truly a marvel of Japanese miniaturization and engineering. This Challenge is an explanation of what exactly happens when you discharge and Airsoft gun.

Springers

Spring guns are driven by a spring, a potential mechanical energy source. The spring propels a piston, which is drawn back by manual force and is internally locked in a rearward position by a sear. When the trigger is pulled, the sear releases the piston creating pressure in the cylinder, which is then channeled through a nozzle and onto the bb which is then propelled out of the barrel.

This basic process is the basis for AEGs, which are more complicated only because the spring compression is accomlished using electric motors instead of by hand.

Gas Guns

The gas gun handles things slightly differently. Instead of using the potential energy crammed into a compressed spring, it uses the energy stored in compressed gasses. The gas is stored inside of a reservoir under pressure in liquid form, the reservoir usually being the gun's magazine. The reservoir has a valve which when opened by a valve knocker inside the gun, creates a channel of pressure difference causing the liquid to expand into a gas, directing the pressure to into the bb to force it out of the barrel. If the gun is a blow back model, some gas is used to propel a piston rearward inside of the slide causing it to fly rearward.

Automatic Electric Guns or AEGs

By far the most complicated and impressive bits of engineering in our sport, the AEG is really what makes this sport so incredibly popular. The ability to produce extended periods of awesome rates of fire with reliability and accuracy is really impressive from such a small package.

"Small?" You say. "My gun is almost 3 feet long and weighs several pounds, how is that small?" Well, the fact is no matter how big your AEG is the fact is there is a very small part of that gun actually doing any work. A vast majority of the rest of it is merely aesthetic trimmings.

You see, an AEG is an electrical driven spring system enclosed in a gearbox. That tiny gearbox runs the entire show. Chemical energy in a battery is converted to mechanical energy by a motor, this motor drives gears which have specific torque and speed ratios corresponding to spring tension.

First is the battery. The battery is stored somewhere on the replica, whether inside of the stock, inside the foregrip, or in any number of external locations. The battery provides the current that causes the motor to turn, explained in detail below.

Second is the magazine. The magazine uses a spring to push the BBs into the replica in order to be fired out of the replica. The BBs are loaded into the magazine, and the magazine is inserted into the replica via the magazine well. When locked into place, the feed tube of the magazine will meet with the feed tube of the magazine well, which is located right under the nozzle on the mechbox, explained below.

Finally, the mechbox and inner barrel. These two devices are they can be removed with AEG disassembly, they are not removable like the magazine, which is intended to be switched out as it runs out of BBs, and the battery which is intended to be removed and recharged or replaced when it can no longer provide enough current to power the motor.

The safety must first be set to a non-safe position. When in safe, it physically blocks the selector plate from moving into a position such that the circuit can be completed. As long as the circuit is broken at this point, the replica will never be able to fire. This is one of two places that the circuit is broken once the battery has been hooked up. The second place is the trigger.

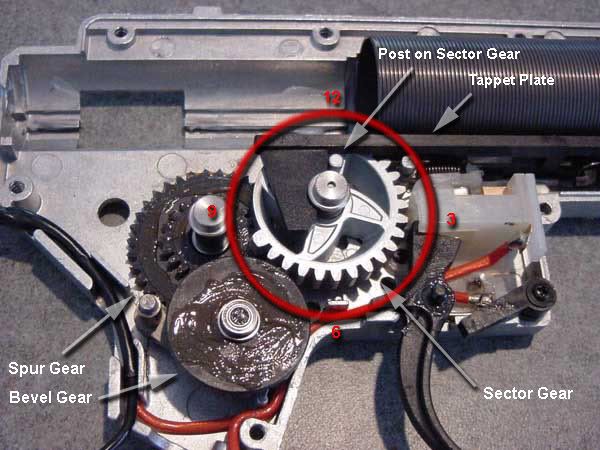

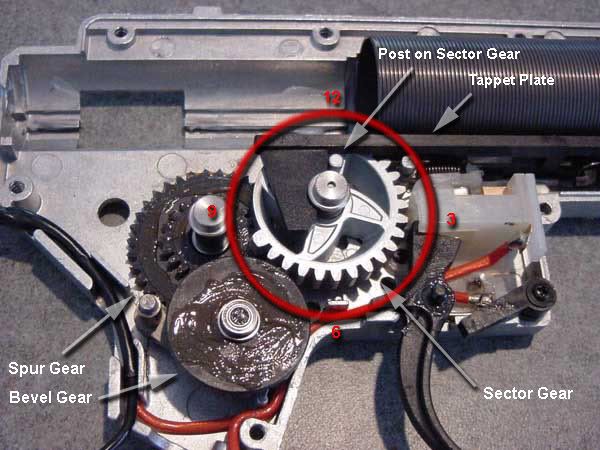

Once the replica is no longer on safe, the trigger is pulled, completing the circuit that enables the motor to start spinning due to the current from the battery. In most AEGs, the motor is located in the grip, and in some AEGs, the motor is actually attached to the mechbox. The teeth on the motor pinion, as the motor turns, turn the bevel gear, which manipulates the spur gear, which then turns the sector gear. ALL activity in the mechbox is based on the sector gear. The gear has a post coming out of the top of the gear, and that post will be used as a reference. In the picture below, the post is just a few minutes past 12 o'clock. This is the chain of events as the sector gear rotates counterclockwise. Times refer to post position.

12:00 - post begins interaction with tappet plate, pushing it towards the rear of the mechbox.

11:00 - teeth on sector gear come into contact with teeth on the piston, and begin to pull back the piston against the resistance of the spring.

The tappet plate is connected to the nozzle, and as the tappet plate is pulled towards the rear of the mechbox, the nozzle is also pulled back. At rest the nozzle prevents BBs from entering the chamber, so once the nozzle is pulled back, one BB is allowed up into the chamber, propelled by the spring inside of the magazine.

9:00 - Nozzle has been moved far enough back that a BB has entered the chamber. The chamber area is only as tall as a single BB, so no additional BBs can enter until the first most BB is out of the way.

7:00 - Post on sector gear has stopped interacting with the tappet plate, and tappet plate returns to rest position. When returning forward, the nozzle also moves forward, pushing the chambered BB into the opening of the hopup assembly, and the nozzle itself is blocking any additional BBs from being loaded.

4:00 - Teeth on the sector gear have now pushed the piston fully towards the rear of the mechbox, with the spring having reached maximum compression on the stroke. Upon further turning, the sector gear no longer has any teeth to interact with the piston, and the coiled spring is able to push the piston forward, back through the cylinder.

The piston moves forward, pushing all air in the cylinder forward, out through the cylinder head and through the nozzle. The cylinder head has an opening in it, which is much smaller in diameter than the cylinder itself. This accelerates the air as it is passing through it. If the cylinder has any holes in it, compression of air doesn't begin until the piston head has passed those holes.

The air comes into contact with the chambered BB, pushing it forward through the inner barrel. Along the way, the BB strikes the hopup membrane (if hopup is present and set). Friction against the membrane puts a backspin on the BB as it travels down the inner barrel, then exiting the replica.

12:00 - The cycle starts over.

When in 'full auto' mode, an AEG simply continues this process until you take away the power source by releasing the trigger. This means it is possible to stop firing when the bolt is in the rearmost position, leaving the spring compressed. Storage of the gun in this state is hard on the internals. This is why they suggest that you fire a few shots in semi-auto at the end of the day, in order to ensure that you do not leave the spring in that compressed state.

Now there are exceptions to this process. Most notably the PSG-1, which is an AEG but isn't capable of automatic fire, like other guns.

The PSG1 semi is different because the piston is already in a thingyed position. When the trigger is pulled, the piston is released and then the gun recycles and the piston is in its original rearward position. This system cuts down the trigger break to shot time, meaning the delay between when you pull the trigger to when a round comes out, is much shorter.

That's how your Airsoft gun works.

Challenge: How do Airsoft guns work?

Thanks to all those who participated!

Contributors to this article include:

519M4 and Pikachoad (who provided the gearbox picture as well as content)

-Jason 'Kornkob' Robinson, Retreat Challenge Editor

We play this game yet few players really understand the internal workings of an Airsoft gun. Where a paintball gun is really a superb example of a simple, hardy machine, an Airsoft gun is truly a marvel of Japanese miniaturization and engineering. This Challenge is an explanation of what exactly happens when you discharge and Airsoft gun.

Springers

Spring guns are driven by a spring, a potential mechanical energy source. The spring propels a piston, which is drawn back by manual force and is internally locked in a rearward position by a sear. When the trigger is pulled, the sear releases the piston creating pressure in the cylinder, which is then channeled through a nozzle and onto the bb which is then propelled out of the barrel.

This basic process is the basis for AEGs, which are more complicated only because the spring compression is accomlished using electric motors instead of by hand.

Gas Guns

The gas gun handles things slightly differently. Instead of using the potential energy crammed into a compressed spring, it uses the energy stored in compressed gasses. The gas is stored inside of a reservoir under pressure in liquid form, the reservoir usually being the gun's magazine. The reservoir has a valve which when opened by a valve knocker inside the gun, creates a channel of pressure difference causing the liquid to expand into a gas, directing the pressure to into the bb to force it out of the barrel. If the gun is a blow back model, some gas is used to propel a piston rearward inside of the slide causing it to fly rearward.

Automatic Electric Guns or AEGs

By far the most complicated and impressive bits of engineering in our sport, the AEG is really what makes this sport so incredibly popular. The ability to produce extended periods of awesome rates of fire with reliability and accuracy is really impressive from such a small package.

"Small?" You say. "My gun is almost 3 feet long and weighs several pounds, how is that small?" Well, the fact is no matter how big your AEG is the fact is there is a very small part of that gun actually doing any work. A vast majority of the rest of it is merely aesthetic trimmings.

You see, an AEG is an electrical driven spring system enclosed in a gearbox. That tiny gearbox runs the entire show. Chemical energy in a battery is converted to mechanical energy by a motor, this motor drives gears which have specific torque and speed ratios corresponding to spring tension.

First is the battery. The battery is stored somewhere on the replica, whether inside of the stock, inside the foregrip, or in any number of external locations. The battery provides the current that causes the motor to turn, explained in detail below.

Second is the magazine. The magazine uses a spring to push the BBs into the replica in order to be fired out of the replica. The BBs are loaded into the magazine, and the magazine is inserted into the replica via the magazine well. When locked into place, the feed tube of the magazine will meet with the feed tube of the magazine well, which is located right under the nozzle on the mechbox, explained below.

Finally, the mechbox and inner barrel. These two devices are they can be removed with AEG disassembly, they are not removable like the magazine, which is intended to be switched out as it runs out of BBs, and the battery which is intended to be removed and recharged or replaced when it can no longer provide enough current to power the motor.

The safety must first be set to a non-safe position. When in safe, it physically blocks the selector plate from moving into a position such that the circuit can be completed. As long as the circuit is broken at this point, the replica will never be able to fire. This is one of two places that the circuit is broken once the battery has been hooked up. The second place is the trigger.

Once the replica is no longer on safe, the trigger is pulled, completing the circuit that enables the motor to start spinning due to the current from the battery. In most AEGs, the motor is located in the grip, and in some AEGs, the motor is actually attached to the mechbox. The teeth on the motor pinion, as the motor turns, turn the bevel gear, which manipulates the spur gear, which then turns the sector gear. ALL activity in the mechbox is based on the sector gear. The gear has a post coming out of the top of the gear, and that post will be used as a reference. In the picture below, the post is just a few minutes past 12 o'clock. This is the chain of events as the sector gear rotates counterclockwise. Times refer to post position.

12:00 - post begins interaction with tappet plate, pushing it towards the rear of the mechbox.

11:00 - teeth on sector gear come into contact with teeth on the piston, and begin to pull back the piston against the resistance of the spring.

The tappet plate is connected to the nozzle, and as the tappet plate is pulled towards the rear of the mechbox, the nozzle is also pulled back. At rest the nozzle prevents BBs from entering the chamber, so once the nozzle is pulled back, one BB is allowed up into the chamber, propelled by the spring inside of the magazine.

9:00 - Nozzle has been moved far enough back that a BB has entered the chamber. The chamber area is only as tall as a single BB, so no additional BBs can enter until the first most BB is out of the way.

7:00 - Post on sector gear has stopped interacting with the tappet plate, and tappet plate returns to rest position. When returning forward, the nozzle also moves forward, pushing the chambered BB into the opening of the hopup assembly, and the nozzle itself is blocking any additional BBs from being loaded.

4:00 - Teeth on the sector gear have now pushed the piston fully towards the rear of the mechbox, with the spring having reached maximum compression on the stroke. Upon further turning, the sector gear no longer has any teeth to interact with the piston, and the coiled spring is able to push the piston forward, back through the cylinder.

The piston moves forward, pushing all air in the cylinder forward, out through the cylinder head and through the nozzle. The cylinder head has an opening in it, which is much smaller in diameter than the cylinder itself. This accelerates the air as it is passing through it. If the cylinder has any holes in it, compression of air doesn't begin until the piston head has passed those holes.

The air comes into contact with the chambered BB, pushing it forward through the inner barrel. Along the way, the BB strikes the hopup membrane (if hopup is present and set). Friction against the membrane puts a backspin on the BB as it travels down the inner barrel, then exiting the replica.

12:00 - The cycle starts over.

When in 'full auto' mode, an AEG simply continues this process until you take away the power source by releasing the trigger. This means it is possible to stop firing when the bolt is in the rearmost position, leaving the spring compressed. Storage of the gun in this state is hard on the internals. This is why they suggest that you fire a few shots in semi-auto at the end of the day, in order to ensure that you do not leave the spring in that compressed state.

Now there are exceptions to this process. Most notably the PSG-1, which is an AEG but isn't capable of automatic fire, like other guns.

The PSG1 semi is different because the piston is already in a thingyed position. When the trigger is pulled, the piston is released and then the gun recycles and the piston is in its original rearward position. This system cuts down the trigger break to shot time, meaning the delay between when you pull the trigger to when a round comes out, is much shorter.

That's how your Airsoft gun works.